Manufacturing facilities operate with two distinct technology environments that rarely speak to each other effectively. Information Technology (IT) systems handle business operations like ERP, finance, and customer management. Operational Technology (OT) systems control manufacturing processes, machinery, and production equipment.

This separation creates data silos that prevent manufacturers from accessing the real-time insights needed for competitive advantage. Production data remains trapped on the factory floor while business decisions get made without understanding operational realities.

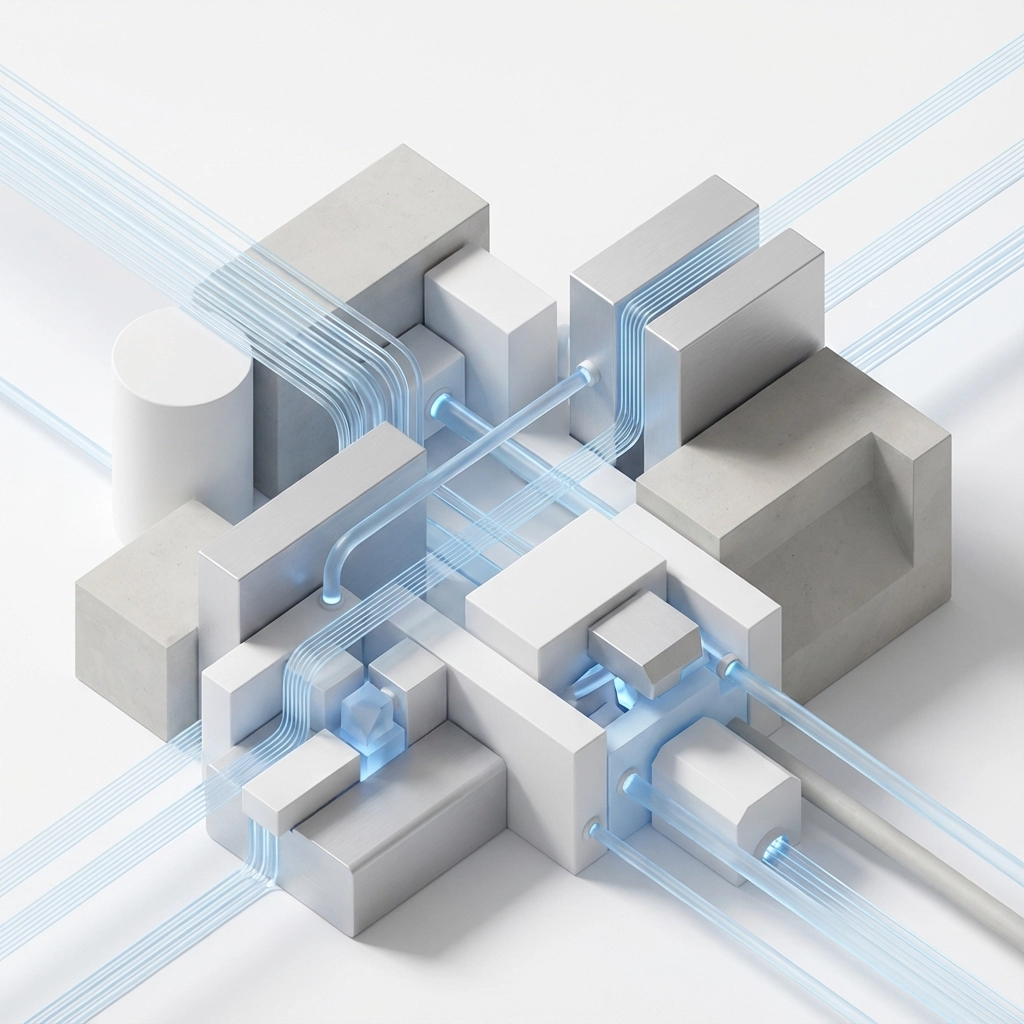

The solution requires a systematic approach to IT-OT integration planning that transforms isolated systems into unified data platforms. Here are five data strategy steps that enable smarter manufacturing decisions.

Step 1: Establish Cross-Functional Teams and Organizational Alignment

Begin by creating dedicated teams that include both IT and OT personnel. These cross-functional groups ensure both perspectives influence decision-making processes and technology implementations.

Organize regular meetings between IT and OT teams to discuss priorities, challenges, and opportunities. IT professionals need to understand production requirements, safety protocols, and operational constraints. OT teams must grasp cybersecurity concerns, data governance standards, and enterprise integration needs.

Start with small collaborative projects to build trust and demonstrate value. Replace handwritten reports and manual data entry with digital alternatives that both teams can access. Connect previously isolated data sources to create shared visibility across departments.

Provide cross-training opportunities so IT staff understand manufacturing processes while OT personnel learn enterprise technology standards. This knowledge transfer eliminates communication barriers and accelerates project delivery.

Document standard procedures for IT-OT collaboration including approval processes, change management protocols, and escalation procedures. Clear governance structures prevent conflicts and ensure consistent implementation approaches.

Step 2: Leverage and Build Upon Existing Data Infrastructure

Avoid wholesale replacement of functional systems. Instead, integrate new solutions on top of existing tools that already meet operational requirements.

Assess current data historians, SCADA systems, and manufacturing execution systems to identify integration opportunities. Many legacy systems contain valuable historical data that provides context for analytics initiatives.

Connect existing systems through standardized interfaces rather than custom integrations. This approach reduces implementation risk, maintains operational continuity, and accelerates return on investment timelines.

Enhance current data collection capabilities with additional sensors and monitoring equipment where gaps exist. Focus on critical process parameters that directly impact quality, efficiency, or safety metrics.

Implement data validation and cleansing procedures to ensure accuracy across integrated systems. Poor data quality undermines analytics initiatives and erodes confidence in automated decision-making capabilities.

Create backup and recovery procedures for critical data sources. Manufacturing operations cannot tolerate data loss that impacts production scheduling or quality tracking systems.

Step 3: Implement Data Visualization and Analytics Capabilities

Deploy visualization tools that present relevant information to different stakeholder groups. Operators need real-time process status while engineers require trend analysis and managers focus on performance metrics.

Create role-based dashboards that filter information according to job responsibilities. Production supervisors access line efficiency data while maintenance teams view equipment health indicators and quality managers monitor defect rates.

Implement alert systems that notify appropriate personnel when parameters exceed acceptable ranges. Automated notifications enable faster response times and prevent minor issues from becoming major problems.

Develop standard reporting templates that provide consistent information across shifts and production lines. Standardized reports facilitate performance comparisons and identify improvement opportunities.

Train users on analytics tools through hands-on workshops and documentation. Effective training ensures widespread adoption and maximizes the value of technology investments.

Establish feedback mechanisms that allow users to request additional features or report system issues. Continuous improvement maintains user engagement and system effectiveness over time.

Step 4: Adopt Standardized Data Integration Platforms and Industry Standards

Implement data integration platforms that aggregate information from multiple sources into unified formats. These middleware solutions handle different communication protocols and translate between system architectures.

Adopt industry standards like OPC-UA that facilitate interoperability between diverse manufacturing systems. Standardized protocols reduce integration complexity and ensure long-term compatibility.

Create master data management procedures that maintain consistent definitions across systems. Product codes, equipment identifiers, and process parameters must align between IT and OT environments.

Implement application programming interfaces (APIs) that enable controlled data sharing between systems. Well-designed APIs provide secure access while maintaining system integrity and performance.

Establish data governance policies that define access permissions, retention periods, and quality standards. Clear governance prevents unauthorized access while ensuring data availability for legitimate business purposes.

Document integration architectures and data flow diagrams for future reference. Comprehensive documentation accelerates troubleshooting and simplifies system modifications.

Step 5: Implement Modern Technology Infrastructure

Deploy edge computing capabilities that process data locally before transmission to enterprise systems. Edge devices reduce network bandwidth requirements while enabling real-time analysis and response.

Implement cloud platforms that provide scalable storage and advanced analytics capabilities. Cloud services offer computational power that exceeds on-premises infrastructure limitations while reducing capital expenditure requirements.

Install cybersecurity solutions designed specifically for OT environments. Traditional IT security tools may disrupt manufacturing operations, requiring specialized approaches that balance protection with operational requirements.

Deploy Industrial Internet of Things (IIoT) sensors that capture previously unmeasured process parameters. Additional data sources provide deeper insights into equipment performance and product quality factors.

Implement network segmentation that isolates critical control systems while enabling controlled data sharing. Proper network architecture prevents cybersecurity incidents from propagating across interconnected systems.

Establish monitoring systems that track network performance and system availability. Proactive monitoring identifies potential issues before they impact manufacturing operations or data collection capabilities.

Measuring Success and Continuous Improvement

Track key performance indicators that demonstrate the value of IT-OT integration initiatives. Monitor metrics like data availability, decision speed, maintenance efficiency, and quality improvements.

Conduct regular assessments of integration effectiveness and identify opportunities for enhancement. Technology capabilities evolve rapidly, requiring periodic evaluation of current implementations against available alternatives.

Gather feedback from system users to understand practical challenges and improvement opportunities. End-user input drives meaningful enhancements that increase adoption and system value.

Plan for scalable expansion that extends successful integration patterns to additional production areas or facilities. Proven approaches can accelerate implementation timelines and reduce project risks.

These five data strategy steps work together to transform manufacturing operations from reactive to predictive. Real-time visibility enables faster problem resolution while historical analysis identifies optimization opportunities. Standardized integration approaches reduce implementation costs and maintenance complexity.

Successful IT-OT integration planning requires commitment from leadership, collaboration between departments, and focus on practical business outcomes. The result is a manufacturing operation powered by data-driven insights that improve efficiency, quality, and competitiveness.

Ready to bridge your IT-OT divide? Contact Bailey & Associates to discuss how our manufacturing IT strategy expertise can help transform your operations through effective data integration.