Having spent over a decade working across food manufacturing at Kanes Foods, St Pierre Group, and Real Good Food PLC, I've seen ERP implementations succeed spectacularly: and fail just as dramatically. The difference rarely comes down to the software itself. It's how you approach the implementation, what you prioritise, and whether you truly understand the unique challenges of food and beverage manufacturing.

As we head into 2026, the stakes are higher than ever. Supply chain disruptions, tightening regulations, and razor-thin margins mean your ERP system isn't just a nice-to-have: it's your operational lifeline. Here are the seven most critical things I've learned about making ERP work effectively in our industry.

1. Start with Compliance, Not Features

Your ERP implementation must begin with regulatory frameworks, not flashy features. During my time at Real Good Food PLC, I watched teams get seduced by impressive dashboards while ignoring the basics of food safety compliance.

Every ERP system in food manufacturing must directly support FSMA, GFSI, SQF, and ISO 22000 requirements from day one. This means built-in traceability, automated certificates of analysis (COAs), QA inspection logs, sanitation records, allergen declarations, and labeling outputs.

The system should enforce compliance automatically, not rely on your team to remember manual steps. When auditors arrive: and they will: you need bi-directional lot tracing, permanent audit trails, and automatic labeling by SKU and market at your fingertips.

2. Involve Your Production Floor, Not Just Your Boardroom

This is where most implementations go wrong. Executives choose the system, IT handles the setup, and production teams get handed the finished product. I've seen this approach fail repeatedly across all three companies I've worked with.

Your QA managers, supply chain leads, and plant supervisors aren't just end users: they're the ones who make the system work. Leave them out of testing and workflow design, and they'll revert to manual workarounds after launch. Every single time.

At St Pierre Group, our most successful ERP updates happened when we brought production supervisors into the planning process from week one. They caught issues in testing that would have caused major headaches post-launch. More importantly, they became champions for the system instead of resistors.

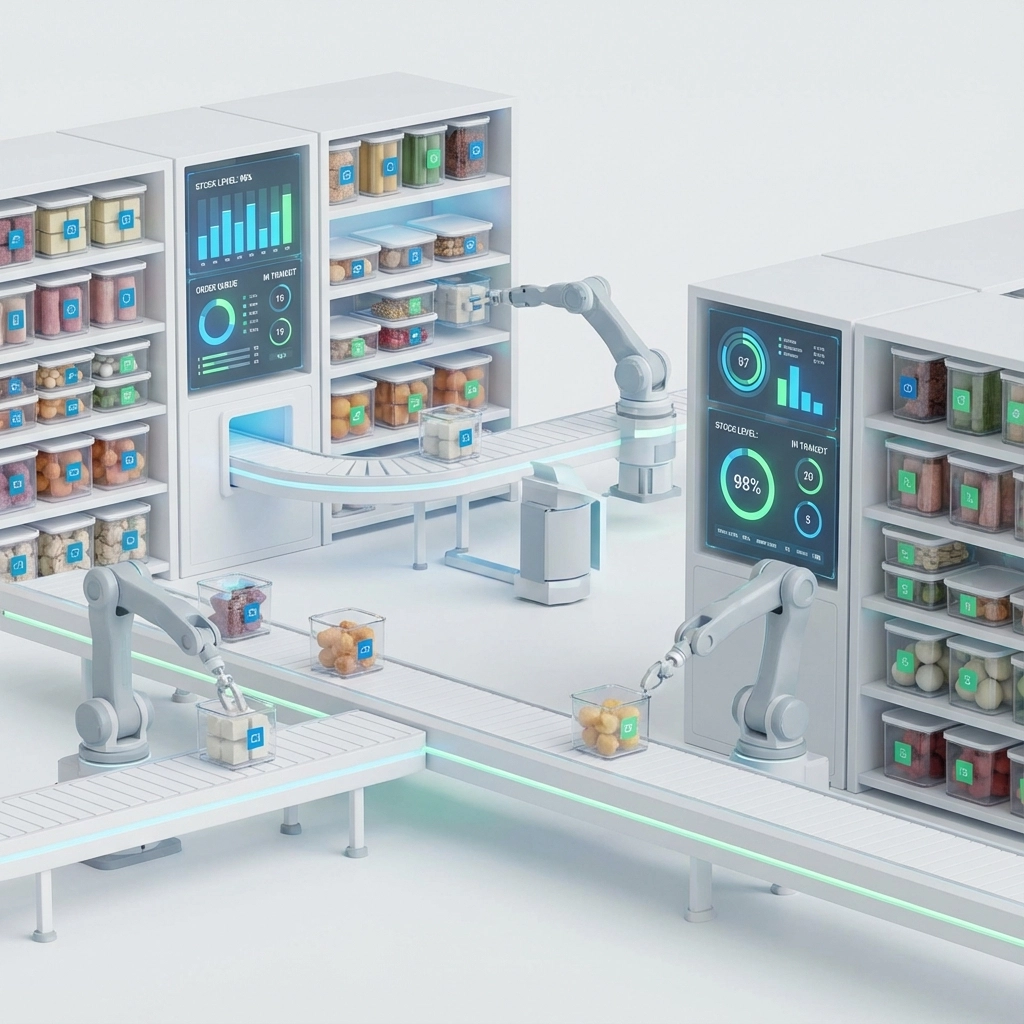

3. Get Your Inventory Logic Right

Food manufacturing inventory isn't like any other industry. You're dealing with expiry dates, temperature controls, batch tracking, and complex formulations where a single ingredient shortage can halt production.

Your ERP must handle FEFO (First Expiration, First Out) logic automatically, with real-time expiry alerts and temperature-sensitive controls. I've seen too many operations still managing this manually in 2025, creating both waste and compliance risks.

Advanced inventory functions should include shelf-life tracking, batch number tracking for every ingredient, and automated replenishment based on actual consumption patterns: not just theoretical planning. When your overnight shift needs to know which lots to use for the morning production run, the system should tell them instantly.

4. Build End-to-End Traceability Into Everything

Traceability isn't optional in food manufacturing: it's survival. But most ERP systems bolt it on as an afterthought instead of building it into every process from procurement to finished goods.

Your system needs to connect QA, production, procurement, and finance through shared data and real-time dashboards. When a quality issue emerges, you can't afford to spend hours tracking down which batches are affected and where they went.

During my time at Kanes Foods, we implemented a system that could trace any ingredient from supplier through finished product in under five minutes. When we had a supplier quality issue, we identified affected batches and contacted customers before the problem escalated. That's the difference between a recall and a minor quality adjustment.

5. Master Recipe and Formulation Management

Dynamic recipe control separates successful food manufacturers from struggling ones. Your ERP should store, manage, and standardise recipes while allowing real-time adjustments based on ingredient availability or cost changes.

This isn't just about consistency: though that's crucial. It's about agility. When your main ingredient supplier has a shortage, you need to reformulate on the fly without compromising quality or regulatory compliance. The system should suggest alternatives, calculate new nutritional information, and update labeling automatically.

Recipe management also means version control. Every change should be tracked, approved, and documented. When you're producing the same product across multiple sites, everyone needs to be working from the same recipe version.

6. Leverage AI-Driven Demand Planning

Food manufacturing operates on thin margins with volatile demand. Traditional forecasting methods don't handle seasonality, promotional spikes, or supply disruptions effectively. AI-driven demand planning has become essential, not optional.

Your ERP should use machine learning to analyse historical data, seasonal patterns, promotional effectiveness, and external factors like weather or economic indicators. This reduces spoilage, minimises stockouts, and helps you react quickly to changing order cycles.

Advanced reporting and analytics should provide real-time insights into overall equipment effectiveness (OEE), product costs, margins, and resource utilisation. When you can see trends developing in real-time, you can adjust production schedules and inventory levels proactively.

7. Choose Industry-Specific Solutions

Generic enterprise systems might work for other industries, but food and beverage manufacturing has unique requirements that general ERP systems handle poorly.

Your system must handle complexity at the batch, lot, and label level while supporting multi-site, multi-brand growth. It needs to understand co-products, by-products, yield variations, and the relationship between raw materials and finished goods.

Look for solutions specifically designed for food manufacturing, with vendors who understand catch weights, recipe scaling, nutritional labeling, and regulatory reporting. The vendor should have deep experience in your specific sector: bakery operations differ significantly from beverage production or meat processing.

Implementation Success Depends on Strategic Partnership

ERP effectiveness comes down to more than software features. It requires treating implementation as a strategic initiative supported by the right partner, a structured roadmap, and commitment from both executive and operational levels.

The most successful implementations I've witnessed combined industry-specific software with vendors who understood our unique challenges. They brought experience from similar operations and could anticipate problems before they occurred.

Your implementation partner should provide ongoing support, regular system optimisation, and strategic guidance as your business evolves. Food manufacturing doesn't stand still, and neither should your ERP system.

At Bailey & Associates, we've helped numerous food and beverage manufacturers navigate these challenges through our Virtual IT Director services. We understand that ERP success requires both technical expertise and deep industry knowledge.

The key is starting with realistic expectations, involving the right people from day one, and choosing solutions designed specifically for food manufacturing challenges. Get these seven elements right, and your ERP system becomes a competitive advantage rather than just an operational necessity.