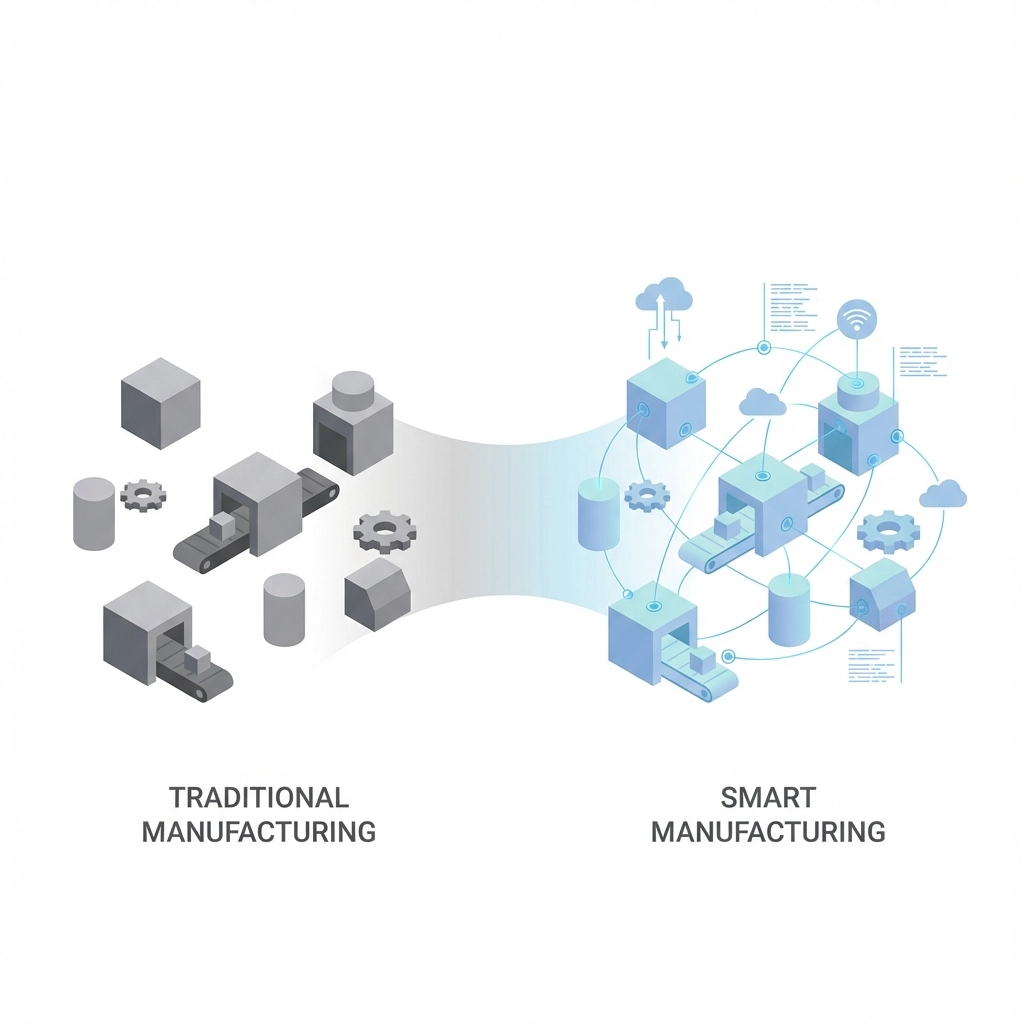

Manufacturing leaders face an uncomfortable truth. Your competitors are making faster decisions with better information. They spot quality issues before products ship. They prevent equipment failures before downtime hits. They optimize production while you're still collecting last week's reports.

The difference is real-time data. It transforms manufacturing from reactive firefighting into proactive optimization. Companies using real-time manufacturing analytics report 15-25% reductions in downtime and 10-20% improvements in overall equipment effectiveness.

The Business Case for Real-Time Manufacturing Data

Real-time data delivers measurable returns across every manufacturing operation. Production managers detect equipment anomalies hours before failures occur. Quality teams catch defects at the source instead of during final inspection. Supply chain coordinators adjust schedules based on actual capacity rather than outdated forecasts.

Manufacturing companies with mature real-time data capabilities consistently outperform competitors. They achieve higher profit margins through reduced waste. They maintain better customer relationships through reliable delivery schedules. They operate more efficiently by eliminating information delays.

The financial impact compounds quickly. A single prevented equipment failure saves thousands in emergency repairs and lost production time. Early defect detection eliminates the cost of reworking entire batches. Accurate capacity data prevents over-committed delivery schedules that damage customer relationships.

Current Manufacturing Data Challenges

Most manufacturing operations collect massive amounts of data but struggle to make it actionable. Production data sits in isolated systems. Quality measurements exist in spreadsheets. Equipment status updates arrive hours after issues occur.

This fragmented approach creates blind spots. Managers make decisions based on incomplete information. Problems escalate before teams discover them. Opportunities for optimization remain hidden in disconnected data sources.

Traditional reporting cycles compound these problems. Weekly production reports arrive too late to prevent quality issues. Monthly equipment summaries miss critical maintenance windows. Quarterly performance reviews identify trends after they impact customer satisfaction.

Manufacturing IT Strategy: Building Real-Time Data Capabilities

Successful real-time data implementation requires a structured approach. Start with clear business objectives. Define specific metrics that drive manufacturing performance. Identify critical decision points that benefit from immediate information access.

Step 1: Assess Current Data Infrastructure

Audit existing manufacturing systems. Document where production data originates. Map how information flows between departments. Identify gaps where critical decisions lack supporting data.

Most manufacturing operations discover significant infrastructure limitations during this assessment. Legacy equipment lacks connectivity options. ERP systems update data in batches rather than real-time. Quality control measurements remain manual processes.

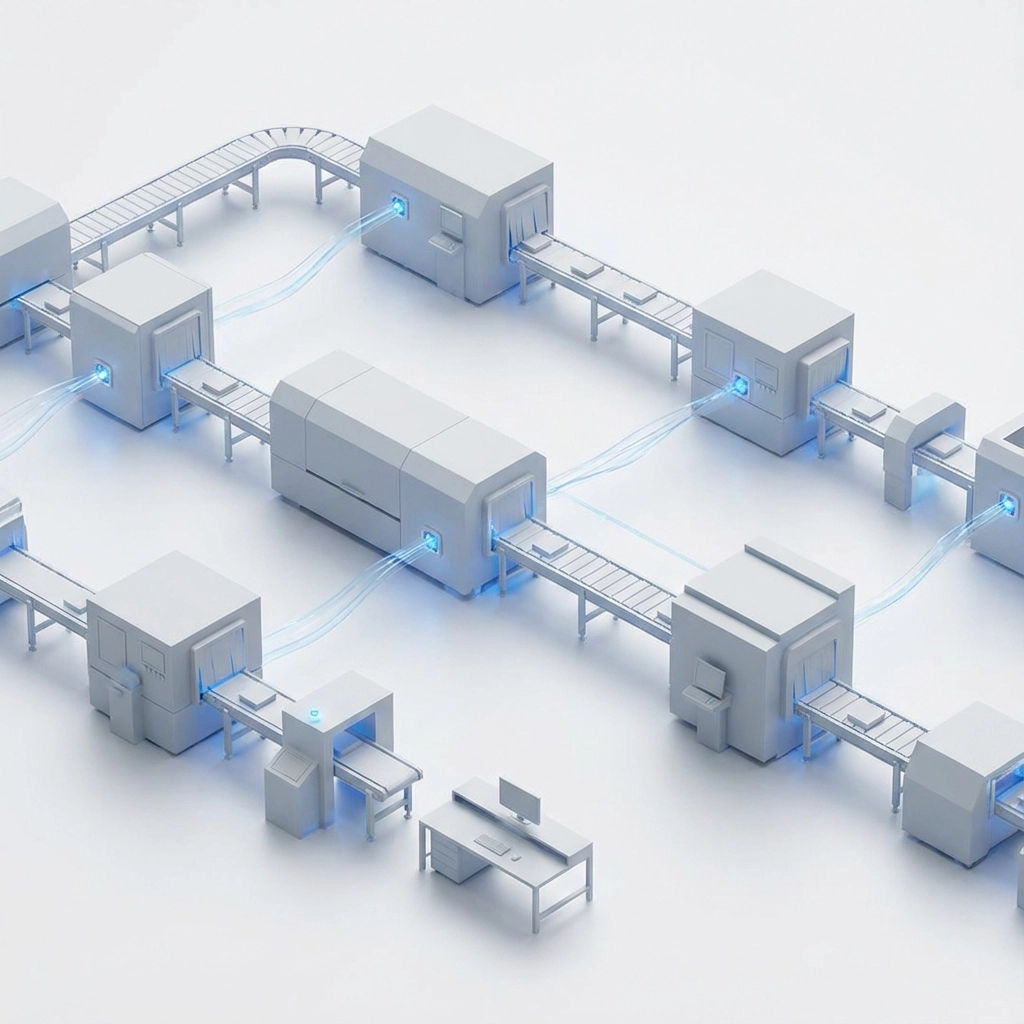

Step 2: Design Data Architecture for Manufacturing Digital Transformation

Plan integrated data architecture that connects operational technology with information systems. Design data flows that capture information at the source. Establish standards for data formatting and transmission protocols.

Edge computing plays a critical role in manufacturing data architecture. Deploy processing capabilities directly on the factory floor. Reduce latency by analyzing data where it originates. Maintain operations even when network connectivity fluctuates.

Step 3: Implement Connectivity Solutions

Install sensors and monitoring equipment on critical manufacturing assets. Connect legacy equipment through industrial IoT gateways. Establish reliable network infrastructure that supports real-time data transmission.

Focus on equipment that directly impacts production efficiency. Start with bottleneck operations where downtime creates the highest costs. Expand connectivity to quality control points and material handling systems.

Step 4: Establish Data Processing and Analytics

Deploy analytics platforms designed for manufacturing environments. Configure automated alerts for critical performance thresholds. Build dashboards that present actionable information to decision makers.

Manufacturing analytics requires specialized approaches. Production data arrives continuously from multiple sources. Quality measurements need immediate correlation with process parameters. Equipment status updates must trigger maintenance workflows automatically.

Step 5: Train Teams and Establish Processes

Develop procedures that leverage real-time information. Train production teams to respond to automated alerts. Establish escalation protocols for critical issues.

Successful implementation depends on organizational change management. Teams need time to adapt to continuous information availability. Managers must learn to trust automated alerts over traditional reporting cycles.

Overcoming Implementation Challenges

Manufacturing digital transformation projects face predictable obstacles. Legacy equipment compatibility limits connectivity options. Network reliability concerns affect data transmission consistency. Staff resistance slows adoption of new processes.

Address compatibility issues through gradual modernization. Replace critical equipment during scheduled maintenance windows. Use industrial gateways to connect legacy systems without major modifications.

Network reliability improves through redundant connectivity and edge processing. Design systems that continue operating during communication disruptions. Store critical data locally until network connections restore.

Staff adoption improves through demonstration of clear benefits. Start with pilot implementations that solve immediate pain points. Show tangible improvements in daily work efficiency before expanding system capabilities.

Measuring Success and Continuous Improvement

Track specific metrics that demonstrate real-time data value. Monitor reduction in unplanned downtime. Measure improvements in first-pass quality rates. Calculate decreases in emergency maintenance costs.

Production efficiency metrics provide clear indicators of success. Overall equipment effectiveness improves when teams prevent failures proactively. Throughput increases when bottlenecks receive immediate attention.

Quality metrics demonstrate customer impact. Defect rates decline when issues receive immediate correction. Customer complaints decrease when problems stop reaching finished products.

Building Long-Term Manufacturing IT Strategy

Real-time data capabilities provide the foundation for advanced manufacturing technologies. Predictive maintenance requires continuous equipment monitoring. Artificial intelligence needs large datasets for accurate predictions. Smart factory automation depends on integrated information systems.

Plan infrastructure investments that support future capabilities. Design data architecture with scalability requirements. Establish partnerships with technology vendors who understand manufacturing environments.

Manufacturing leaders who invest in real-time data capabilities today gain competitive advantages that compound over time. They make better decisions faster. They prevent problems before they impact operations. They optimize performance continuously rather than periodically.

The question is not whether to pursue real-time manufacturing data. The question is how quickly you can implement capabilities that your competitors may already be using against you.

Ready to develop a comprehensive manufacturing IT strategy that delivers real-time insights? Contact Bailey & Associates to discuss how our Virtual IT Director services can accelerate your manufacturing digital transformation without the overhead of full-time executive hiring.