Manufacturing leaders face a critical question when planning their digital transformation: does IoT technology secure operations or expose them to new vulnerabilities? The answer requires examining current security realities rather than marketing promises.

The IoT Security Reality Check

IoT is currently creating significant security risks rather than securing manufacturing shop floors. Despite operational benefits, manufacturers frequently overlook these vulnerabilities while pursuing smart factory initiatives.

Your manufacturing IT strategy must address this fundamental imbalance. While IoT enables predictive maintenance, real-time production monitoring, and enhanced supply chain visibility, these capabilities introduce serious security trade-offs that traditional IT approaches cannot handle.

Understanding Manufacturing-Specific IoT Vulnerabilities

Manufacturing environments face unique security challenges that differ from typical corporate IT threats. These vulnerabilities require specialized attention in your manufacturing digital transformation planning.

Unmanaged Device Proliferation

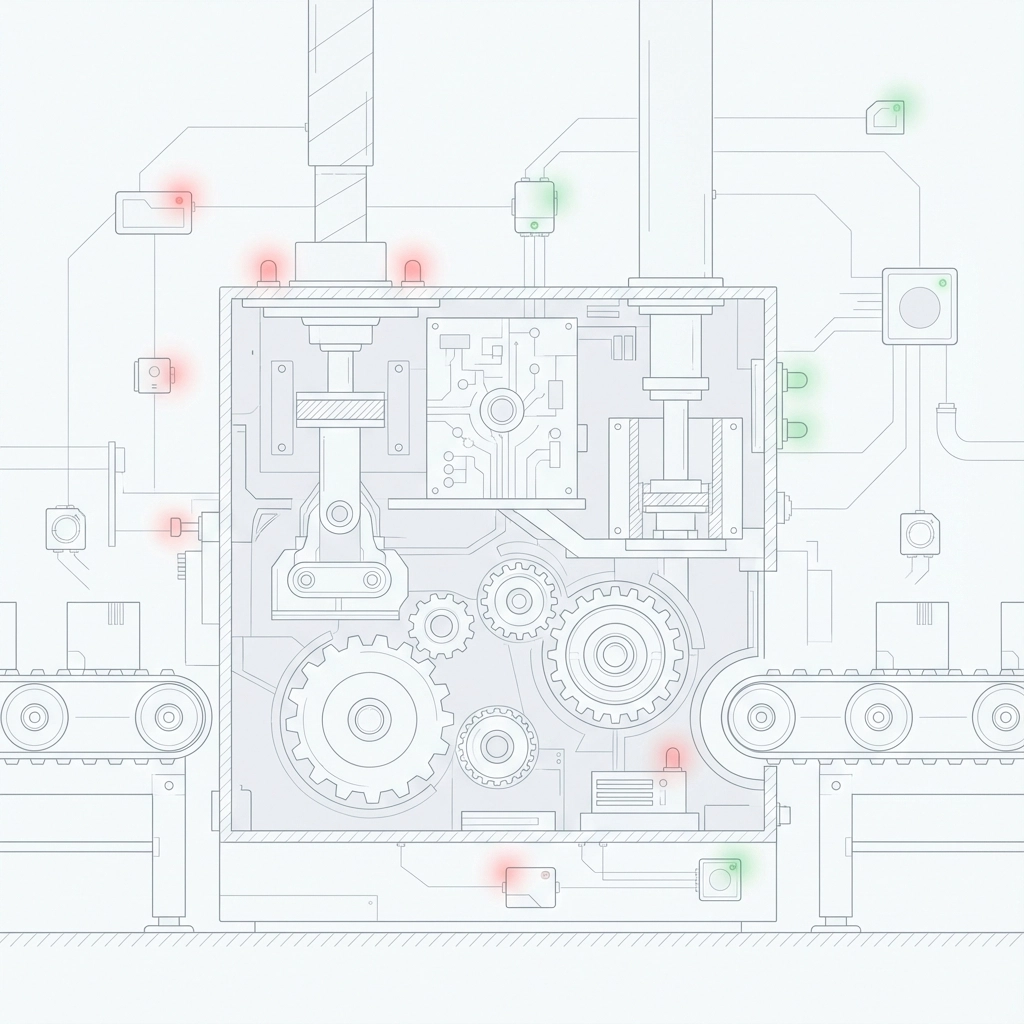

Your shop floor likely contains numerous IoT devices with limited security capabilities. Sensors, controllers, and monitoring equipment often lack standard protections such as anti-malware, anti-virus, and on-device monitoring systems.

Bad actors can target these sensors to gain broader network access. A compromised sensor or control system can halt entire production lines, creating operational and financial damage beyond typical data breaches.

Supply Chain Security Gaps

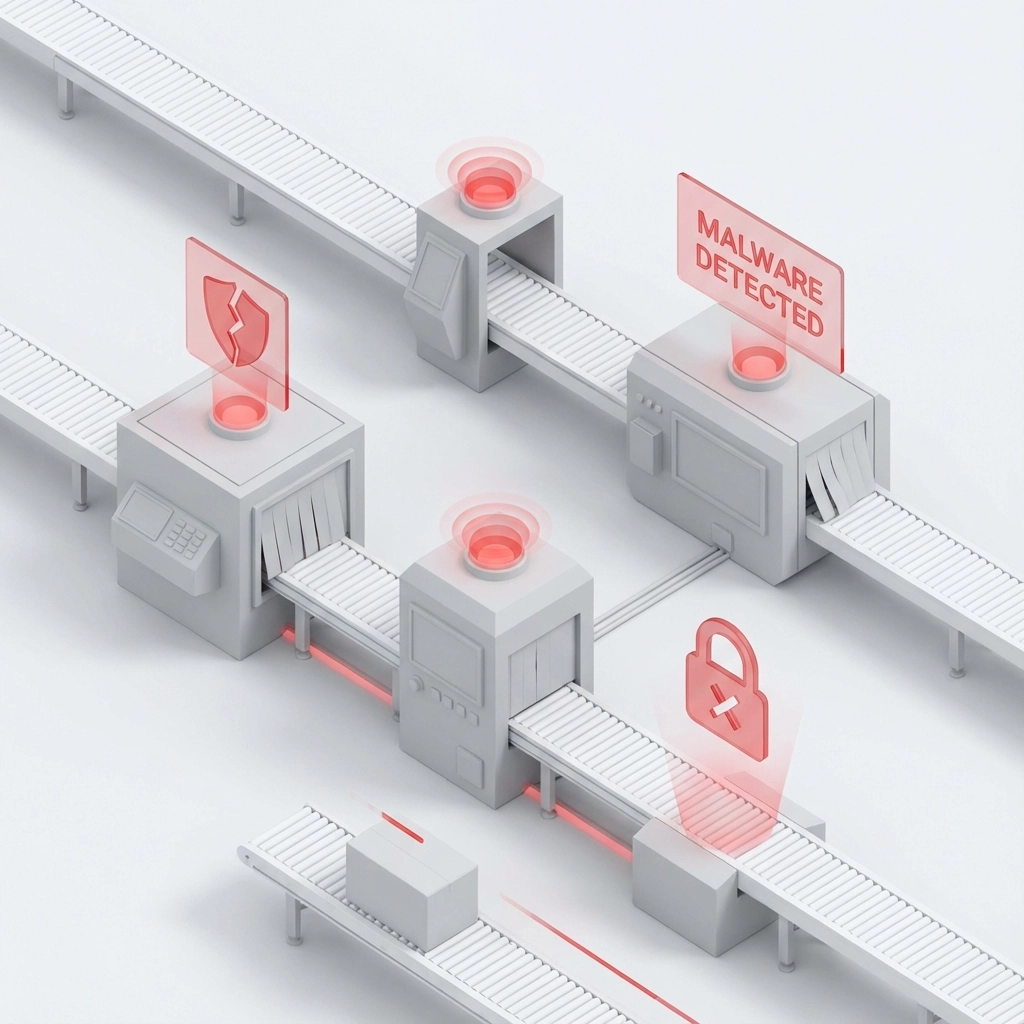

Security weaknesses begin at the component level. Microcontrollers arriving at manufacturing plants often come as blank, unlocked devices. This creates opportunities for malicious code injection during the manufacturing process itself.

Out-of-the-box Industrial IoT devices frequently contain zero-day vulnerabilities that attackers monitor and exploit. Your manufacturing IT strategy must account for these inherent weaknesses when evaluating new equipment.

Shadow IT in Manufacturing

Vendors, contractors, and engineering teams often add devices during upgrades or troubleshooting without updating IT systems. This creates blind spots that undermine your security posture and complicate compliance efforts.

Smart factory consulting engagements frequently reveal dozens of untracked devices operating on production networks. These devices represent potential entry points for cybercriminals seeking to disrupt operations or steal intellectual property.

Critical Risk Areas in Connected Manufacturing

Manufacturing environments face threats that extend beyond traditional cybersecurity concerns. Understanding these risks helps prioritize your security investments and operational procedures.

Physical Safety Threats

Manufacturing cybersecurity incidents can result in harm to human life, equipment damage, and facility destruction. Unlike corporate environments where breaches typically involve data theft or ransomware, manufacturing attacks can cause physical damage and endanger workers.

Your security review must evaluate how IoT devices could impact worker safety if compromised. Consider scenarios where attackers manipulate temperature controls, safety systems, or equipment operation parameters.

Intellectual Property Exposure

Connected devices create new pathways for intellectual property theft. Insecure IoT channels can expose proprietary manufacturing processes, product designs, and operational data to competitors or cybercriminals.

Manufacturing digital transformation initiatives must include IP protection strategies that account for data flowing through IoT networks. This includes both internal communications and external vendor connections.

Operational Disruption Vectors

Attackers targeting manufacturing environments often seek to disrupt operations rather than steal data. IoT devices provide multiple entry points for these attacks, from sensor manipulation to control system interference.

Your manufacturing IT strategy should include rapid response procedures for IoT-related incidents. Consider how quickly you could isolate compromised devices while maintaining essential operations.

Why Traditional Security Approaches Fail in Manufacturing

Manufacturing environments present unique challenges that standard IT security approaches cannot adequately address. Understanding these limitations helps develop more effective protection strategies.

Legacy System Integration Challenges

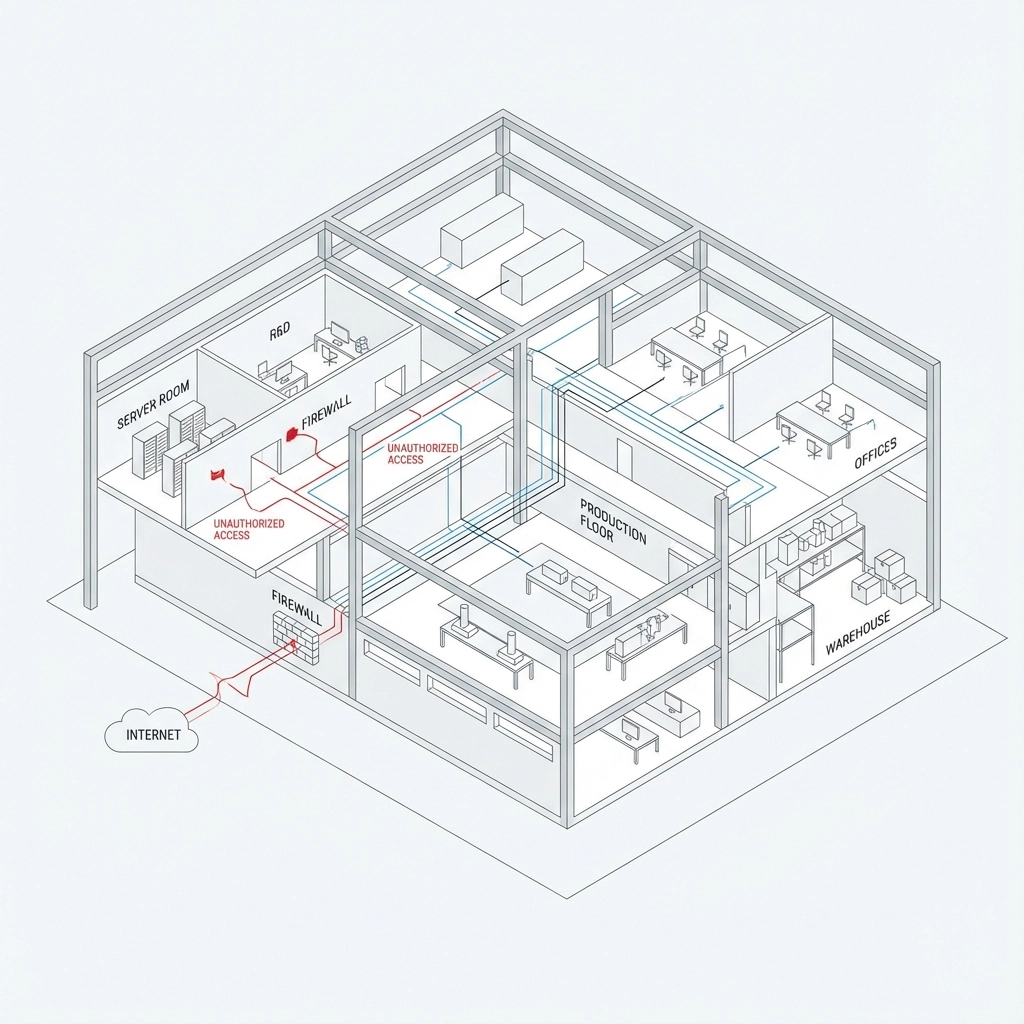

Many manufacturing facilities operate legacy systems alongside new IoT devices. These older systems often lack modern security features and cannot receive regular updates.

Your smart factory consulting process must evaluate how IoT devices interact with legacy equipment. Develop strategies for creating security boundaries between old and new systems without disrupting production workflows.

Operational Priority Conflicts

Manufacturing operations prioritize uptime and productivity over security in many situations. This creates tension when implementing security measures that could impact production schedules.

Successful manufacturing IT strategy balances security requirements with operational needs. Identify critical production periods when security updates or system changes should be avoided.

Resource and Expertise Gaps

Just 21% of organizations have fully implemented internal programs to address insider threats related to connected devices. Many manufacturing companies lack dedicated cybersecurity staff with IoT expertise.

This gap creates opportunities for external smart factory consulting services to provide specialized knowledge and ongoing support for IoT security management.

Implementing Effective IoT Security Controls

Protecting your manufacturing environment requires proactive security measures designed specifically for IoT devices and industrial networks. These controls must integrate with your broader manufacturing digital transformation strategy.

Device Discovery and Monitoring

Start by identifying all connected devices in your environment. Implement monitoring solutions such as Microsoft Defender for IoT or Claroty to detect threats from malicious sources or device malfunctions.

Your security review should include comprehensive device inventories that track device types, network connections, and security capabilities. Update these inventories regularly as new equipment is installed or existing devices are modified.

Risk Assessment and Prioritization

Conduct thorough risk assessments that evaluate potential impacts of device compromises. Consider operational disruption, safety implications, and data exposure risks for each device category.

Prioritize security investments based on these risk assessments. Focus initial efforts on devices that could cause the most significant operational or safety impacts if compromised.

Governance and Procurement Controls

Establish governance procedures for device procurement and network access. Require security evaluations for new IoT devices before installation and operation.

Your manufacturing IT strategy should include vendor security requirements and ongoing compliance monitoring. This prevents the introduction of vulnerable devices and maintains security standards across your connected infrastructure.

Network Segmentation Strategies

Implement network segmentation to isolate IoT devices from critical systems and corporate networks. This limits potential attack spread and provides better control over device communications.

Smart factory consulting engagements often reveal opportunities for improved network architecture that enhances both security and operational efficiency.

Building Long-Term IoT Security Capabilities

Sustainable IoT security requires ongoing attention and capability development rather than one-time implementations. Your approach must evolve with changing threat landscapes and expanding device deployments.

Continuous Monitoring and Response

Deploy automated monitoring systems that can detect anomalous device behavior and potential security incidents. Develop response procedures that allow rapid isolation of compromised devices while maintaining production continuity.

Regular security reviews help identify new vulnerabilities and ensure existing controls remain effective as your environment changes.

Skills Development and Training

Invest in cybersecurity training for operations and engineering staff who interact with IoT devices. This helps prevent security incidents caused by configuration errors or unsafe practices.

Consider partnering with external experts for specialized knowledge and ongoing support. Smart factory consulting services can supplement internal capabilities while building long-term organizational knowledge.

Strategic Planning Integration

Integrate IoT security considerations into your broader manufacturing digital transformation planning. This ensures security requirements are addressed early in project planning rather than added as afterthoughts.

Your manufacturing IT strategy should include regular security architecture reviews that evaluate how new technologies and processes impact overall security posture.

Moving Forward with Confidence

IoT technology offers significant operational benefits for manufacturing organizations, but these benefits come with serious security responsibilities. Success requires acknowledging current vulnerabilities while implementing comprehensive protection strategies.

Focus your efforts on understanding your specific risk profile, implementing appropriate controls, and building ongoing security capabilities. This approach enables you to capture IoT benefits while protecting your operations, workers, and competitive advantages.

Regular security reviews and strategic planning help ensure your smart factory initiatives enhance rather than undermine your overall security posture. The key is treating security as an enabler of digital transformation rather than an obstacle to overcome.