Manufacturing leaders invest heavily in technology to stay competitive. ERP systems, MES platforms, IoT sensors, and cloud infrastructure promise efficiency gains and cost savings. Yet many manufacturers watch their tech investments deliver disappointing results: or worse, create new problems that hurt production.

The culprit isn't usually the technology itself. It's poor vendor management.

When you lack proper oversight of your technology suppliers, you're essentially writing blank checks while hoping for the best. Your production line depends on these vendors performing as promised, but without the right management framework, you're setting yourself up for costly failures.

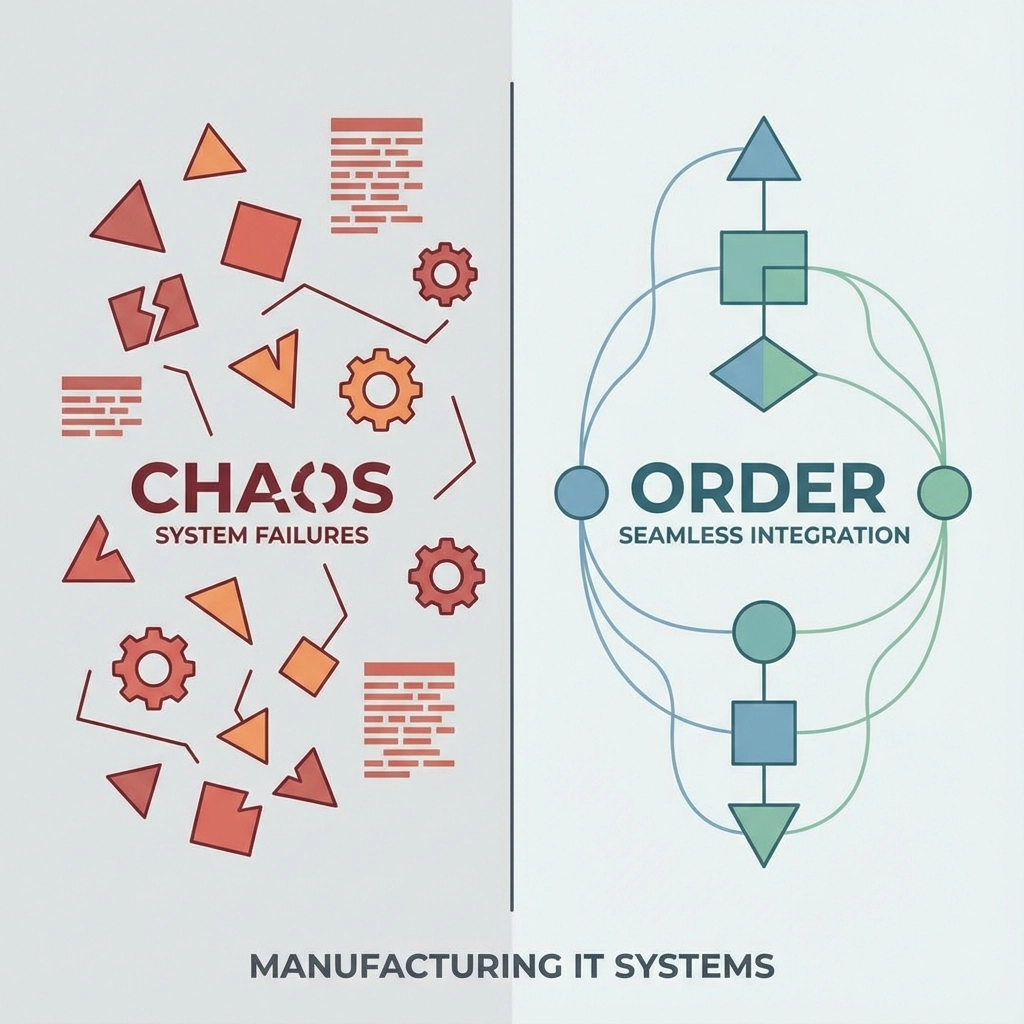

How Poor Vendor Management Sabotages Manufacturing Investments

Manufacturing operations can't afford the cascading failures that poor vendor management creates. Here's how weak oversight undermines your technology investments.

Uncontrolled Costs and Vendor Lock-In

Without proper contract management, vendors gradually expand their scope and increase fees. Your ERP implementation that started at £50,000 suddenly requires additional modules, consulting hours, and "essential" upgrades that weren't in the original agreement. Before you know it, you're paying triple the initial quote with no clear path to switch providers.

Manufacturing companies often find themselves locked into expensive maintenance contracts with legacy system vendors who know switching costs are prohibitive. One automotive parts manufacturer we encountered was paying £180,000 annually for support on a 15-year-old system because they never established exit clauses or data portability requirements in their original contract.

Production Downtime from Vendor Failures

Poor vendor performance monitoring means you discover problems only when they impact production. Your MES system crashes during a critical production run because your cloud provider experienced an outage you weren't notified about. Your predictive maintenance software fails to alert you about bearing failures because the IoT sensor vendor hasn't been maintaining their firmware updates properly.

These failures aren't just inconvenient: they're expensive. Manufacturing downtime costs can reach £50,000 per hour or more for complex production lines. When vendor failures cause these disruptions, poor management practices mean you lack the documentation and SLAs needed to recover costs or enforce accountability.

Compliance Gaps and Regulatory Risks

Manufacturing faces strict regulatory requirements around data handling, environmental reporting, and quality management. When vendors fail to meet compliance standards, your entire operation is at risk.

Consider a pharmaceutical manufacturer whose quality management system vendor couldn't demonstrate GDPR compliance during a regulatory audit. The resulting investigation delayed product launches by six months, costing millions in lost revenue. This could have been prevented with proper vendor due diligence and ongoing compliance monitoring.

Data Silos and Integration Failures

Without strategic vendor management, you end up with disconnected systems that can't share data effectively. Your ERP system can't communicate with your warehouse management system. Your quality control platform operates in isolation from your production planning tools. Your financial reporting requires manual data extraction from multiple vendor systems.

These integration failures prevent you from gaining the operational visibility that drove your technology investments in the first place. You're paying for multiple systems but getting fragmented insights that make informed decision-making nearly impossible.

What Great Manufacturing IT Directors Do Instead

Effective manufacturing IT leaders treat vendor management as a strategic capability, not an administrative task. They implement systematic approaches that protect investments and drive measurable results.

Conduct Rigorous Manufacturing-Specific Due Diligence

Before selecting any technology vendor, experienced IT directors evaluate their manufacturing credentials thoroughly. They verify the vendor's experience with similar production environments, regulatory requirements, and integration challenges.

For ERP vendors, this means examining their track record with companies of similar size and complexity in your industry. For IoT platform providers, it means understanding their experience with your specific equipment types and communication protocols. For cloud providers, it means verifying their uptime history and disaster recovery capabilities for mission-critical manufacturing applications.

Smart IT directors also assess vendor financial stability. Manufacturing technology implementations often span multiple years, so you need confidence that your vendor will remain viable throughout the project lifecycle and beyond.

Build Comprehensive Performance Agreements

Rather than accepting generic service level agreements, manufacturing IT directors negotiate specific, measurable performance metrics aligned with production requirements.

For your MES platform, this might mean guaranteed 99.9% uptime during production hours with specific response times for critical alerts. For your ERP system, it could include maximum batch processing times for end-of-day production reporting. For IoT sensors, it might specify data accuracy tolerances and communication reliability standards.

These agreements include clear escalation procedures and financial penalties for non-performance. When a vendor failure costs you production time, you have documented processes to recover those costs rather than absorbing them as "the cost of doing business."

Establish Clear Governance Structures

Successful manufacturing IT directors create vendor management frameworks with defined roles and responsibilities. The procurement team handles contract negotiations and vendor onboarding. Production managers monitor day-to-day performance and flag operational issues. Finance tracks spending and contract renewals. IT manages technical integration and security compliance.

This structure prevents situations where vendor issues fall through cracks because nobody owns the relationship. Each stakeholder understands their role in vendor success, and clear communication channels ensure problems get escalated appropriately.

Implement Continuous Performance Monitoring

Rather than discovering vendor problems during crisis situations, effective IT directors establish ongoing monitoring systems. They track vendor performance against agreed SLAs through automated dashboards that provide real-time visibility into system availability, response times, and service quality.

Regular business reviews with vendor account managers: and escalation to vendor executives when necessary: ensure performance issues get addressed proactively. These reviews cover not just technical performance but also strategic alignment, roadmap updates, and emerging challenges that could impact manufacturing operations.

Maintain Vendor Diversification and Risk Management

Smart manufacturing IT directors avoid over-dependence on single vendors for critical functions. They maintain relationships with backup suppliers and ensure their systems can operate with alternative providers if necessary.

This doesn't mean constantly switching vendors, but rather maintaining optionality and negotiating contracts that preserve your ability to change direction when vendor performance deteriorates or business needs evolve.

They also conduct regular risk assessments that evaluate vendor financial health, security posture, and compliance status. Changes in vendor circumstances get identified early, allowing proactive response rather than reactive crisis management.

Focus on Strategic Value, Not Just Cost

While cost management remains important, experienced manufacturing IT directors evaluate vendors based on total value delivered rather than initial price quotes. A slightly more expensive ERP vendor that offers better integration capabilities and faster implementation might deliver superior ROI compared to a low-cost provider that requires extensive customization.

They consider factors like vendor innovation roadmaps, industry expertise, and long-term partnership potential. Manufacturing technology investments often last 5-10 years or more, so vendor selection decisions should optimize for sustained value rather than short-term savings.

Transform Vendor Relationships Into Strategic Assets

Manufacturing IT vendor management done right transforms supplier relationships from necessary expenses into strategic advantages. When your vendors understand your production requirements and regulatory constraints, they become partners in driving operational excellence rather than external resources you must constantly monitor and manage.

The manufacturers that excel at vendor management invest in these capabilities early and maintain them consistently. They recognize that in an increasingly connected manufacturing environment, vendor performance directly impacts their competitive position.

If your manufacturing operation struggles with vendor-related technology failures, cost overruns, or integration challenges, the solution isn't better vendors: it's better vendor management. The framework and processes that effective IT directors use can be implemented in any manufacturing environment, regardless of size or complexity.

Ready to transform your manufacturing IT vendor relationships from liability into competitive advantage? The systematic approach that works for industry leaders can work for your operation too.