Most manufacturing SMEs know they need to modernise their IT infrastructure, but many don't know where to start. You've heard about AI transforming factories, smart manufacturing, and Industry 4.0, but your current systems feel light-years away from that reality.

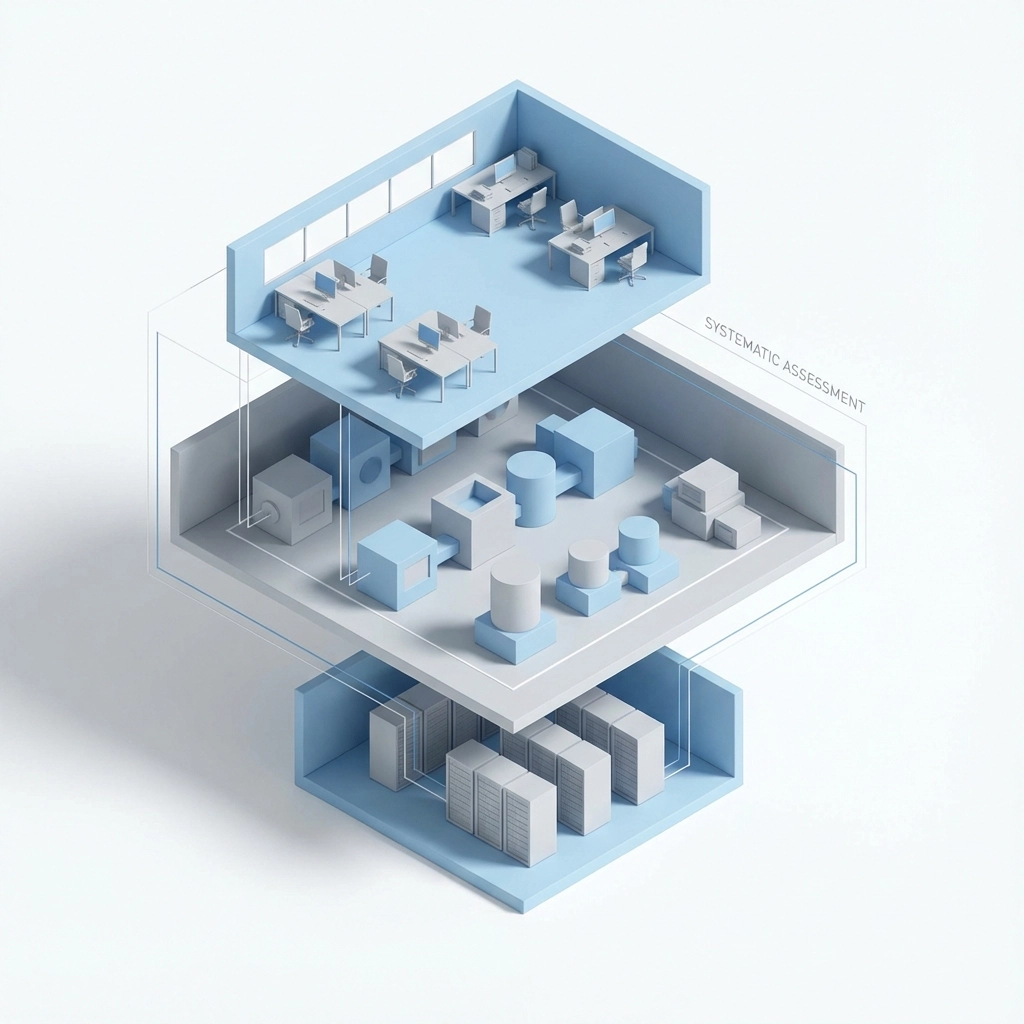

The good news? You don't need to overhaul everything overnight. Manufacturing digital transformation succeeds when you take a systematic, phased approach that builds AI-readiness into your foundation from day one.

This guide walks you through five essential steps to conduct IT reviews that prepare your manufacturing business for AI integration and smart factory evolution.

Step 1: Conduct Your Initial IT Assessment

Start with a comprehensive evaluation of your current technological state. Document every system, process, and piece of technology currently in use across your manufacturing operation.

What to Document

Create an inventory that includes:

- All existing software systems (ERP, accounting, production planning tools)

- Hardware infrastructure (servers, workstations, manufacturing equipment)

- Network capabilities and internet connectivity

- Current data collection methods

- Integration points between different systems

- Staff technical skill levels

Key Assessment Questions

Answer these fundamental questions to establish your baseline:

- Are your business processes automated or manual?

- Do you use data analytics to make operational decisions?

- Are your systems integrated with each other?

- Do you have cloud-based solutions in place?

- Is your production process digitally monitored?

- How do you currently track inventory, quality, and performance?

This assessment reveals which areas would benefit most from technology investments and establishes measurable starting points for your transformation journey.

Step 2: Foundation Phase Implementation (0-6 Months)

Your first implementation should focus on creating a solid digital foundation that supports future AI capabilities. Start with minimal Manufacturing Execution System (MES) functionality.

Begin with Basic MES

Implement core MES features that enable:

- Production planning and scheduling

- Work instruction execution

- Real-time production tracking

- Basic quality control documentation

This foundation allows you to collect accurate, clean data from every tracked process: the fuel that powers future AI applications.

Essential Digital Infrastructure

Simultaneously upgrade these basic systems:

- Document Management: Digitise essential documents, work instructions, and quality procedures

- Financial Systems: Upgrade accounting software to handle digital workflows

- Communication Tools: Implement digital communication platforms for real-time coordination

- Staff Training: Provide basic digital skills training to your team

These foundational changes eliminate manual data entry errors, improve information flow, and prepare your organisation for more advanced capabilities.

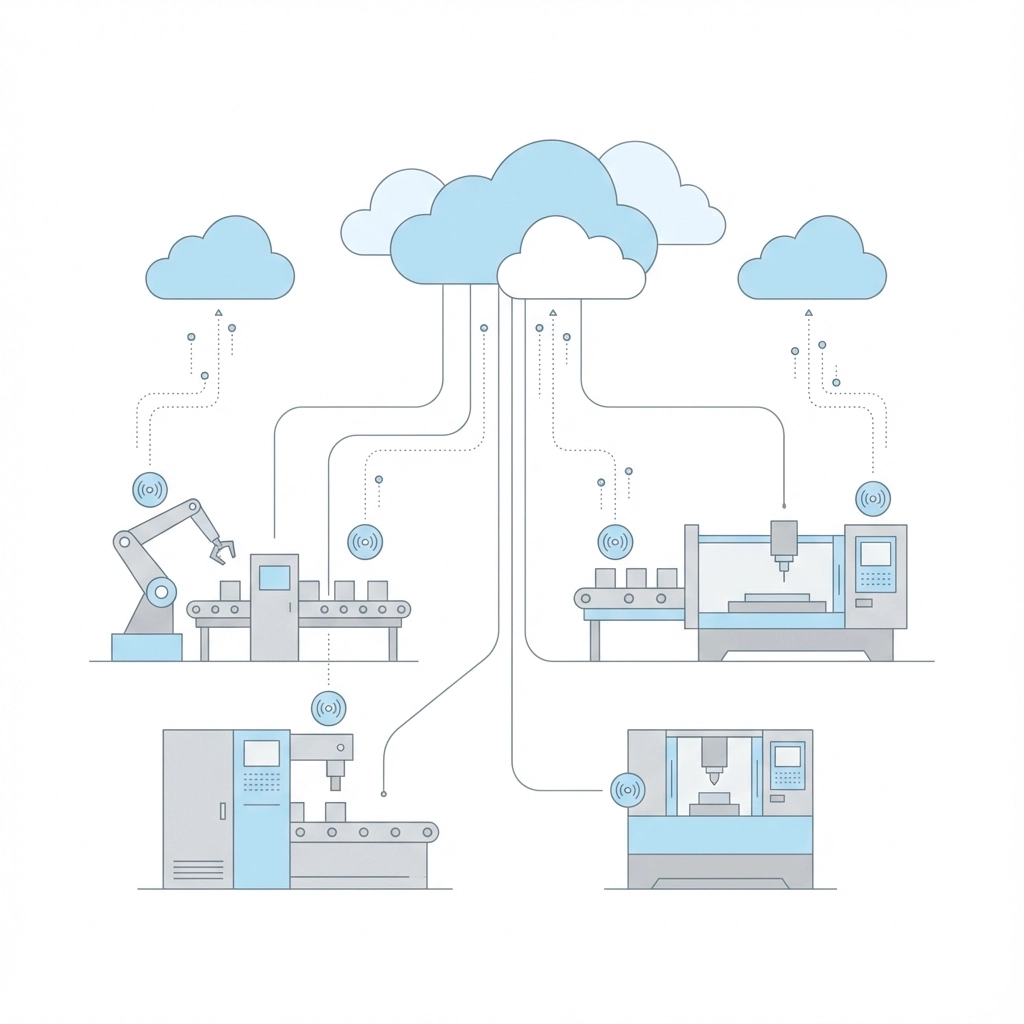

Step 3: Prioritise AI-Ready Technologies

Focus your technology investments on systems that position your manufacturing operation for AI integration. These technologies create the infrastructure needed for smart factory evolution.

Cloud Computing Infrastructure

Cloud platforms provide the computational power and storage capacity essential for AI applications. Start with:

- Cloud-based data storage for production information

- Scalable computing resources for data processing

- Remote access capabilities for monitoring and management

- Backup and disaster recovery systems

IoT Sensor Networks

Internet of Things (IoT) sensors connect your production equipment to gather operational data continuously. Begin with:

- Temperature and humidity monitoring for quality control

- Equipment performance sensors for predictive maintenance

- Energy consumption monitoring for efficiency optimisation

- Production count sensors for real-time throughput tracking

Data Analytics Platforms

Build capabilities to analyse patterns and forecast trends: prerequisites for effective AI implementation:

- Business intelligence dashboards for production metrics

- Statistical process control for quality management

- Trend analysis for demand forecasting

- Performance benchmarking against industry standards

Step 4: Operational Efficiency Phase (7-12 Months)

Once your foundation is established, deploy systems that improve operational efficiency while gathering valuable data for future AI applications.

Inventory Management Systems

Implement inventory management with barcode or QR scanning capabilities:

- Real-time stock level tracking

- Automatic reorder alerts

- Lot tracking for quality control

- Integration with production planning systems

Production Tracking Enhancement

Upgrade production tracking to provide comprehensive visibility:

- Real-time workflow monitoring

- Bottleneck identification and analysis

- Performance metrics against planned targets

- Quality control integration

Business Intelligence Implementation

Deploy business intelligence tools that transform raw data into actionable insights:

- Production performance dashboards

- Quality trend analysis

- Cost tracking and optimization recommendations

- Predictive analytics for maintenance scheduling

Step 5: Build Your Strategic Roadmap

Create a comprehensive roadmap that guides your ongoing manufacturing digital transformation efforts and positions your business for smart factory consulting opportunities.

Define Measurable KPIs

Establish key performance indicators aligned with your business objectives:

- Overall Equipment Effectiveness (OEE) improvements

- Quality defect reduction percentages

- Energy consumption efficiency gains

- Production throughput increases

- Customer satisfaction score improvements

Create Implementation Timeline

Develop a realistic timeline that includes:

- Quarterly milestones for each transformation phase

- Budget allocation for technology investments

- Staff training and development schedules

- Integration testing and validation periods

- Performance review and adjustment cycles

Resource Allocation Planning

Plan how to allocate budget and staff to each initiative:

- Technology investment priorities

- Internal vs external implementation resources

- Training and development costs

- Ongoing maintenance and support requirements

- Change management and communication efforts

Overcoming Common Transformation Barriers

Recognise that resistance to change, legacy infrastructure constraints, and upfront investment costs are common challenges in manufacturing digital transformation.

Address Change Resistance

Build momentum through small wins that demonstrate clear value:

- Automated production scheduling that reduces planning time

- Improved inventory accuracy that prevents stockouts

- Enhanced quality tracking that reduces customer complaints

- Real-time performance monitoring that enables quick problem resolution

Manage Legacy System Integration

Work around legacy infrastructure limitations by:

- Implementing middleware solutions for system integration

- Using APIs to connect new systems with existing equipment

- Phasing equipment upgrades to spread costs over time

- Maintaining hybrid manual-digital processes during transition periods

Optimise Investment Returns

Maximise your technology investment returns by:

- Starting with high-impact, low-cost implementations

- Leveraging cloud solutions to reduce upfront infrastructure costs

- Building on earlier successes to justify additional investments

- Measuring and communicating ROI regularly to stakeholders

Next Steps for Your AI-Ready Transformation

This phased approach to manufacturing digital transformation allows you to spread investment over time, build on earlier successes, and adjust plans based on lessons learned. Each phase creates value independently while preparing your foundation for advanced capabilities like artificial intelligence and machine learning.

Begin with your IT assessment this week. Document your current state, identify quick wins, and establish your transformation timeline. The manufacturing SMEs that start their digital transformation journey today will be the smart factories of tomorrow.

Consider working with experienced smart factory consulting professionals who understand manufacturing operations and can guide your transformation journey. The right partnership accelerates your progress while avoiding common implementation pitfalls that delay results and increase costs.

Your AI-ready manufacturing future starts with today's IT review. Take the first step and begin building the foundation that powers tomorrow's competitive advantages.